Decoding 3D Printers: What They Actually Look Like And Why

Introduction

The world of 3D printing has evolved rapidly with impressive strides in technology. It's a brave new world where digital models turn into tangible objects before our eyes, bringing concepts, prototypes, and solutions to life. However, a common question posed by those new to this technology is, 'What does a 3D printer look like?' Seems simple, but there are layers to this question that we will unravel in this article. From their basic setup to the core components and different types to future models—you're in for a comprehensive dive into the unique look of 3D printers and why they are designed the way they are.

What is a 3D Printer and What Does it Look Like?

A 3D printer is an innovative piece of technology that translates digital designs into physical objects using a layer-by-layer fabrication process. Despite vast varieties, a 3D printer typically has a characteristic appearance shaped by several key features:

- Structure: The printer appears in a cuboid design quite similar to traditional printers but with a larger size to accommodate the 3D printing process.

- Display: It includes a more distinctive display and control panel for navigation and commands.

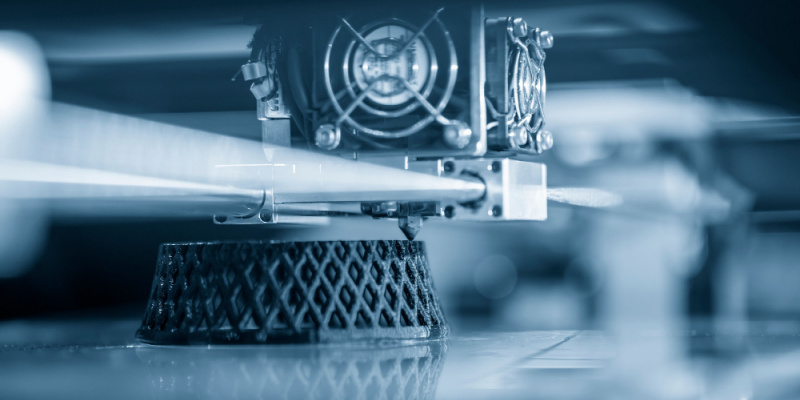

- Print Bed and Extruder: The housing area of the printer contains essential elements like a print bed, which is the platform where printing takes place, and an extruder, adjusting the object's dimensions as per the design.

- Material: The printer uses varying materials like plastic, nylon, resin, or even metal, depending on the model and purpose.

- Design Variances: The final look of a 3D printer varies substantially based on the function it serves, its cost, and the specific printing technology it employs.

Exploring Different Types of 3D Printers: Do They All Look the Same?

Evidently, 3D printers, much like the objects they produce, come in a variety of shapes and sizes. While they all share the primary purpose of creating detailed three-dimensional items, their design can vary greatly depending on the printing technology utilized. Here's a rundown of the main types that offer us a glimpse into their unique design structures:

1. Fused Deposition Modeling (FDM) Printers:

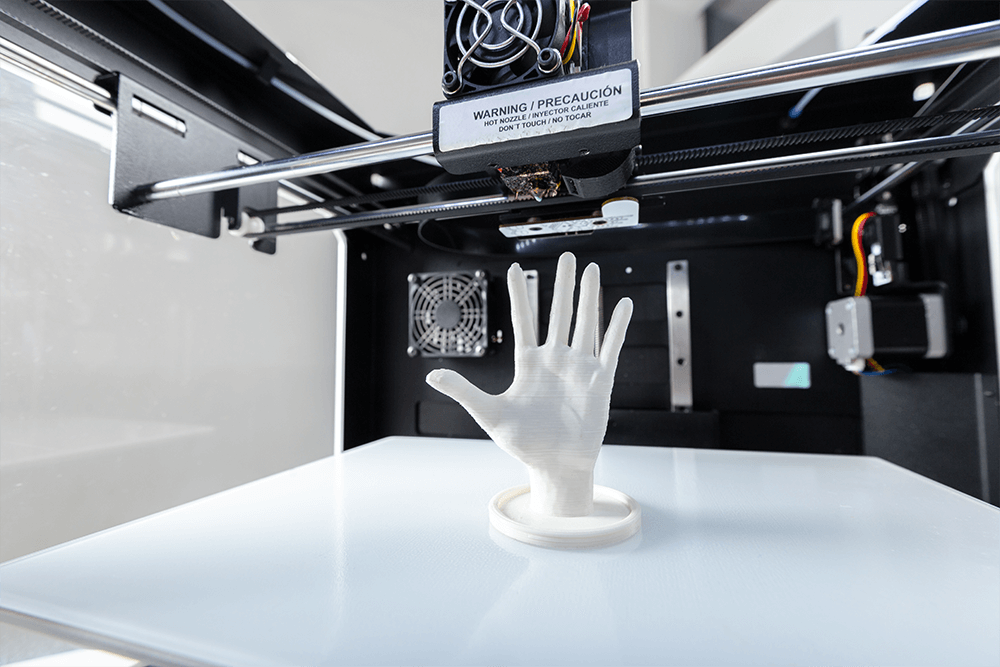

-Description: FDM printers are known as the most prevalent type in the 3D printing community. Their modus operandi includes heating a plastic filament and extruding it layer by layer to craft the desired object's shape.

-Design: Usually, FDM printers have a box or cube-like design—they often feature a visible printing area and come equipped with a filament spool holder.

2. Stereolithography (SLA) Printers:

-Description: SLA printers operate differently—they solidify liquid resin using a UV laser to form layers of the designed object.

-Design: SLA printers generally possess a distinct hooded area covering the laser operating site—this set-up aids in the specific printing process they follow.

3. Selective Laser Sintering (SLS) Printers:

-Description: SLS printers work by employing high-powered lasers to fuse tiny particles of plastic, ceramic, or glass into precise 3D shapes.

-Design: Their design is a bit more intricate and typically sealed, primarily because the materials used are in a powdery form, and the process involves a fair amount of heat.

Confirming our hypothesis, 3D printers do not flaunt identical designs—the specific printing technology each utilizes shapes their distinct look and constituent features.

Understanding the Core Components of 3D Printers: What Makes up Their Unique Appearance?

The particular design of 3D printers is traceable to their fundamental components. These hardware elements not only define their aesthetic look but also play a pivotal role in their functionality. Each of these components collectively contributes to the fascinating world of 3D printing.

• Control Panel: The control panel serves as the printer’s command center. Positioned for easy access, it is a critical feature that gives 3D printers their unique modern appearance.

• Extruder: The extruder, responsible for heating and depositing the printing material, is another distinctive feature of 3D printers. Its size and location can greatly influence the printing speed and resolution, adding to the character of these machines.

• Print Bed: This is where layering happens. Its flat surface and adjustment capabilities contribute to the box-like shape of these printers.

• Spool Holder: Specifically seen in Fused Deposition Modelling (FDM) printers, the spool holder stores the plastic filament and adds to the unique look of these printers.

• UV Laser System and Resin Vat: Stereolithography (SLA) printers feature a vat that contains liquid resin and a UV laser system under a hooded area, contributing to their signature look.

• Powder Bed and Laser System: In Selective Laser Sintering (SLS) printers, you’ll spot a complex, sealed design to encapsulate the powder bed and the powerful laser system.

• 'X-Y-Z' Axes: The 3D movement controls in these printers also add to their distinctive look with its clear enclosures for safe and detailed viewing of the printing process.

Exploring the design of 3D printer components paints a comprehensive picture of why they look the way they do, ultimately enhancing our understanding and appreciation of this captivating technology.

How Do the Looks of 3D Printers Interplay with Their Functions?

The design elements of a 3D printer go beyond simply contributing to its aesthetic value, in fact, they play a crucial role in how efficiently the printer functions. Here, we explore how each major component impacts a printer’s overall functionality:

1. Enclosed Designs: Many 3D printers sport enclosed designs. This is not merely a design choice, but it serves a practical purpose of maintaining a uniform temperature within the printer. This is crucial for creating strong and sturdy prints.

2. The Extruder: The size and position of the extruder greatly influence the speed and resolution of printing. A bigger extruder can allow for quicker printing but might compromise on fine details and vice-versa.

3. The Control Panel: The location and layout of the control panel can directly impact usability and control of the printer. A strategically placed, user-friendly control panel facilitates easier navigation and operation.

4. Spool Holder in FDM Printers: In FDM printers, the design and positioning of the spool holder can affect how smoothly the filament feeds into the extruder, thus affecting the print quality.

5. Printer Body Color and Material: Interestingly, even the color and material of the printer body can influence its functionality. Certain materials and colors might absorb or dissipate heat more efficiently, which indirectly affects the printing quality.

In conclusion, the look of a 3D printer intertwines heavily with how well it performs – from the arrangement of components, their encasing, to even the color and material choices, each aspect contributes to functionality. This serves to remind us that the design of a 3D printer does not merely satisfy the eye, but it plays a pivotal part in the printing process, ultimately impacting the final product's quality.

What Might the 3D Printers of the Future Look Like?

The unparalleled advancements in technology will create a significant impact on what 3D printers might look like in the future. Factors such as evolving user experience, and the pressing need for sustainability are likely to shape their design. Here’s what to expect:

1. Aesthetics and Compactness: Future 3D printers will likely emphasize a sleeker and more compact look. As more consumers adopt these devices for everyday use and home applications, manufacturers will focus on making them lightweight and easily portable.

2. Improved User Interfaces: Future models might contain highly intuitive control panels, aiming to make the 3D printing process more manageable for the average user. This might include features like touch screens, improved sensors, and advanced software.

3. A More Interactive Viewing Process: Printers may feature larger in-built transparent sections, giving users the visual satisfaction of watching their creations take form in real time.

4. Noise and Heat Management Features: Anticipate seeing designers incorporating noise and heat reduction strategies into the look of future 3D printers. This could involve novel materials, strategic air vents, or discreet, built-in cooling systems.

5. Sustainability-Focused Design: An increasing need to be environment-friendly will likely influence the look and function of future printers. Expect features like:

- On-board recycling mechanisms for reusing materials

- Biodegradable or recycled print materials

- Energy-efficient power systems

In conclusion, the future will likely yield a new generation of 3D printers–more streamlined, user-friendly, and environmentally conscious. It is an exciting time in the world of technology as we brace ourselves for these forthcoming changes.

Conclusion

3D printers are complex yet intriguing devices that have revolutionized the world of production and design. By understanding the elements of their appearance—and how those elements impact function—you gain a deeper appreciation for these transformative machines. Keep in mind, though, that the look of 3D printers is not static but evolving with advancements in technology and shifts in user and environmental needs.

Related FAQs about what do 3d printers look like

What are the different types of 3D printers and how do their appearances differ?

There are three main types of 3D printers: Fused Deposition Modeling (FDM) printers, Stereolithography (SLA) printers, and Selective Laser Sintering (SLS) printers. FDM printers operate by heating a plastic filament and are usually cuboid in shape. SLA printers solidify liquid resin with a UV laser and have a distinct hooded design. SLS printers fuse tiny particles through high-powered lasers into 3D shapes and have a complex, typically sealed design.

Can the design of a 3D printer affect its performance?

Absolutely, the design of a 3D printer directly impacts its performance. For example, the size and position of the extruder can influence the speed and resolution of printing. The design and positioning of a spool holder, particularly in FDM printers, also affect how smoothly filament feeds into the extruder, impacting the overall print quality.

How has the design and look of 3D printers changed over the years?

Over the years, the design and look of 3D printers have evolved significantly. Earlier models were bulky and complex, but modern units are more compact, user-friendly, and aesthetically appealing. Future printers may feature even more streamlined designs with advanced interfaces, improved viewing processes, and eco-friendly materials while focusing on efficient power usage.