Exploring the Multifaceted Application of 3D Printers

Introduction

The advent of 3D printing technology has ushered in a game-changing era that is redefining multiple sectors worldwide. From revolutionizing healthcare to altering the face of construction, automotive, and education, the multifaceted applications of 3D printers are too significant to ignore. This article offers an insight into the various ways 3D printers are being utilized, providing a deep-dive into how they function, their impact across different industries, and what the future may hold. So, let's take a closer look at what are the uses of 3D printers.

What Is 3D Printing and How Do 3D Printers Work?

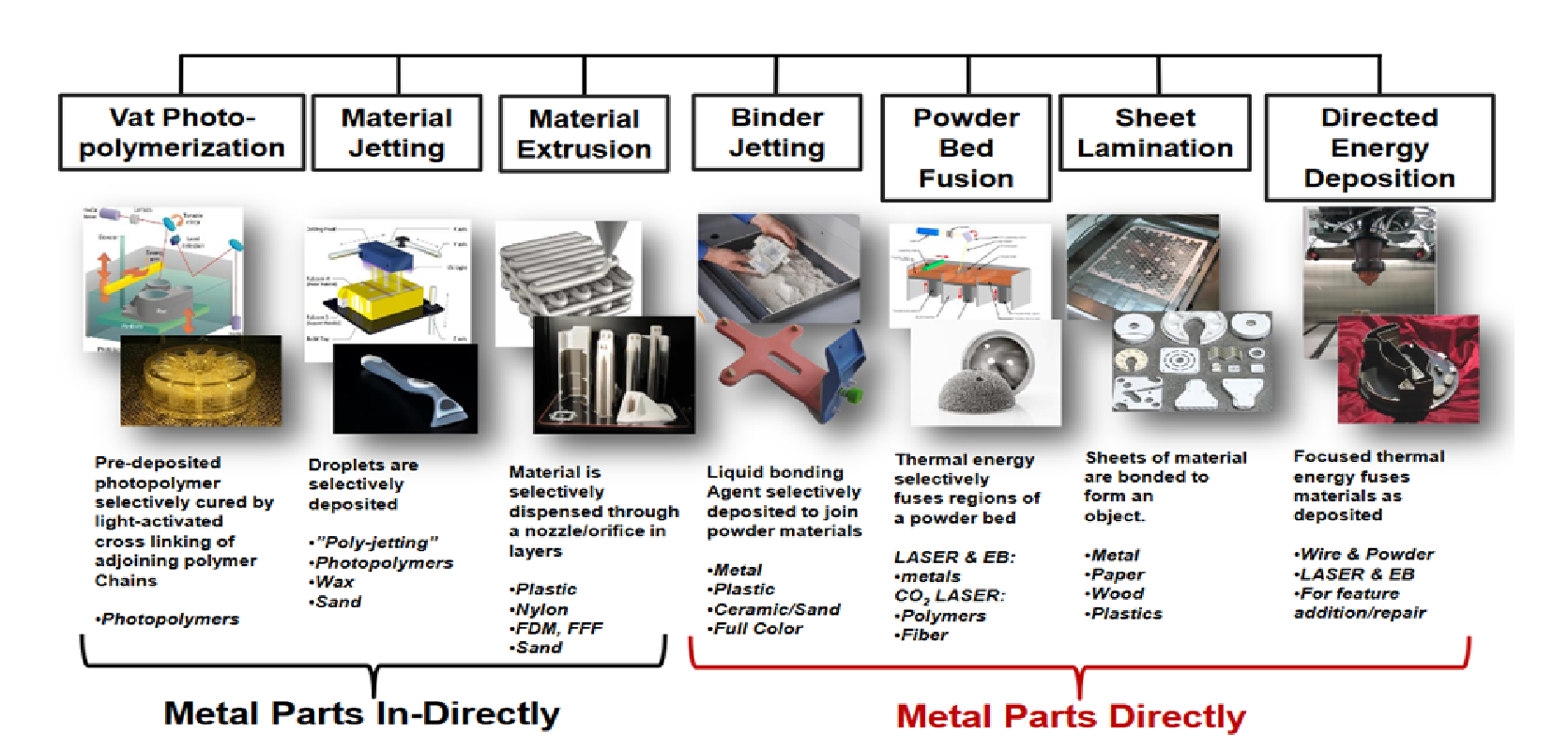

3D printing, or additive manufacturing, is a powerful technological tool that operates based on a digital layout to form three-dimensional objects. Wondering about the nuts and bolts of how 3D printers work? Here's a simpler explanation:

- Digital Blueprint: 3D printing starts off with a digital design of the object to be printed. This design serves as a blueprint which is usually created on modeling software like Computer-Aided Design (CAD).

- Layering Process: Often referred to as an "additive process", 3D printing utilizes layering techniques. It deposits materials like plastic, metal, or ceramics in layers to construct the required object.

- Material Fusion: How do the multiple layers stay together? 3D printers either melt or soften the material, which is then laid down in precise patterns under the strict supervision of computer control, subsequently fusing the layers to create the final three-dimensional masterpiece.

While this may sound complex, modern advancements have made 3D printing strikingly accessible for various industries and even individuals, who are now capable of creating anything from intricate designs to life-sized prototypes. The age of 3D printing is here, revolutionizing the world as we know it.

How Are 3D Printers Reshaping Healthcare?

3D printers are shaping the future of healthcare, offering a range of potential life-changing applications. From speeding up medical device development to pioneering new ways of treating diseases, this advanced tool is transforming the field.

- Tailor-made Prosthetics: Advancements in 3D printing technology have made it possible to design bespoke prosthetics. These custom-fit devices greatly enhance the comfort and mobility of amputee patients. Notably, statistics from Johns Hopkins Medicine estimate that 40% more amputees now prefer 3D-printed prosthetics due to their enhanced comfort levels and affordability.

- Innovative Bio-printing: Another revolutionary breakthrough is the development of bio-printing. Utilizing specially-formulated bio-inks made from live cells, healthcare professionals are beginning to print functional tissue. While still in the exploratory stage, experts anticipate this technology could eventually facilitate organ printing - a transformative change for organ transplantation.

- Rapid Prototyping: 3D printing allows for rapid production and customization of medical equipment. Faster prototyping means speedier invention cycles, which, in turn, can accelerate new treatment development.

- Medical Models: Physicians can now make use of 3D printed patient-specific models to plan surgeries and educate patients about their treatment. This ultimately improves the outcome of complex surgeries and enhances patient understanding.

In a nutshell, the adoption of 3D printing technology in healthcare is paving the way for less invasive treatments, better patient outcomes, and greater efficiencies within the sector.

How Are 3D Printers Revolutionizing the Construction Industry?

3D printers are extending their reach far beyond small-scale objects, venturing into the realm of large-scale construction. From erecting homes to offices, and even sophisticated bridges, these robust machines are weaving magic.

Below are some key ways in which 3D printers are impacting the construction industry:

1. Eco-friendly Construction: One of the key roles of 3D printers in the construction industry is sustainability. They work by layering a special blend of concrete as per a pre-set design. This targeted use of material minimizes waste, promoting more environmentally-friendly practices.

2. Improved Efficiency: 3D printers increase efficiency in construction. They speed up the traditional building process, significantly reducing labour costs and delivering structures more promptly.

3. Cutting-edge Architectural Structures: Utilizing 3D printers in construction has ushered in an era where complex, innovative architectural structures that would be challenging to achieve with conventional methods can now be created.

4. Affordability: While one may think that this revolutionary technology would be expensive, the opposite is true. The precise use of materials and its labor-saving properties make 3D printed buildings more affordable.

In essence, 3D printers are redefining the construction industry. Exciting times lie ahead as this technology is poised to usher in a more sustainable, efficient, and aesthetically diverse era of construction.

What is the Role of 3D Printers in the Automotive Industry?

The motorsport world is witnessing a transformative shift as 3D printing technology revamps design processes, prototyping, and the production of custom parts. Here's how 3D Printers are revolutionizing the automotive industry:

1. Accelerating Design Processes: Traditional methods of designing automobile parts can be time-consuming. 3D printing technology slashes the time taken, facilitating rapid development of new designs and bringing them to production faster.

2. Prototyping Efficiency: Car manufacturers no longer need to rely on molds or tooling for initial prototypes. Instead, 3D printers enable them to create parts directly from CAD files, substantially reducing costs and offering an efficient method of iterative design alterations.

3. Production of Custom Parts: 3D printing provides an opportunity for personalization. Customers can have input into creating unique, bespoke parts for their vehicles, enhancing personal ownership experiences and catering to specific requirements.

4. Producing Lighter and Stronger Parts: 3D-printed automotive parts can be customized to an extent that isn't possible with traditionally manufactured components. They can be designed to be both lighter and stronger, which leads to improved fuel efficiency and overall performance.

5. Emerging Concepts: The advancements of 3D printers also enable the production of complete cars and intricate motorcycle parts. Consistently evolving, the scope of 3D printing continues to expand in the automotive industry.

In a nutshell, 3D printing in the automotive industry not only accelerates design and prototype development but also opens doors for innovation and customization, potentially reshaping the future landscape of the sector.

How Can 3D Printers Be Used in the Education Sector?

The advent of 3D printing technology in the field of education is fostering creativity in young minds, enhancing understanding, and setting groundwork for future professionals. A strong tool to bridge the gap between the complexities of theoretical knowledge and practical applications, its usage is remarkably impactful.

• Hands-on Learning Experience: 3D printing propels the process of interactive learning, allowing students to convert abstract ideas into palpable models. This aligns with the "learning by doing" strategy, which significantly improves comprehension.

• Visualization: Facilitating tactile experiences can help students better grasp complicated concepts. For instance, providing physical models created from 3D printers in a biology class can help students to visualize the theoretical concepts effectively.

• Creativity and Innovation: With 3D printing technology, mundane classes are transformed into lively workshops, enhancing students' creative skills. Practical exposure encourages inventive thinking, presenting a new perspective to look at conventional problems.

• Preparation for the future: As technology evolves, so does its implications in various industries. Including 3D printing in the curriculum will better equip students for careers in engineering, design, healthcare and others.

• Promoting problem-solving skills: From designing the model in a specific software to rectifying errors when the design doesn't come out as expected, the entire process of 3D printing imparts problem-solving skills.

Embedding the application of 3D printing technology in education can stimulate minds and foster a forward-thinking approach in students. By encouraging an immersion of technologically advanced tools like 3D printers in education systems, we are shaping the ground for an innovative and technologically advanced future.

(Words: 251)

Conclusion

3D printing technology is redefining the traditional methods of manufacturing, delivering heightened efficiency, innovation, and customization. It's a tool with vast potential that transcends sectors and disciplines. From healthcare to the automotive industry, the multifaceted applications of 3D printers are beautifully reimagining conventional practices, promising a future of endless possibilities.

Related FAQs about what are the uses of 3d printers

What are some unique uses of 3D printers across different industries?

3D printers are being utilized in a multitude of industries, radically transforming traditional practices. In healthcare, they're used for creating tailor-made prosthetics, bio-printing tissues, and rapid prototyping. In construction, they assist in building eco-friendly structures more efficiently and affordably. Within the automotive industry, they're pivotal in accelerating design processes, producing custom parts, and improving prototyping efficiency. Additionally, in education, they foster practical learning, stimulate creativity, and pave the way for an innovative future.

How has 3D printing impacted traditional methods of manufacturing?

3D printing has revolutionized the conventional methods of manufacturing by offering faster, cost-effective, and more flexible processes. It allows for rapid prototyping, which shortens design cycles and accelerates product development. This technology also reduces waste produced during manufacturing, promoting sustainability. Furthermore, 3D printing enables the production of complex designs bypassing traditional restrictions and facilitates the customization of products to individual specifications.

What could be some future applications of 3D printing technology?

Future prospects for 3D printing technology are vast and transformative. In the medical sector, it may enable the printing of viable human organs for transplantation. For construction, entire advanced cities could be built efficiently using 3D printers. In the automotive industry, it could facilitate mass production of fully 3D-printed cars. Lastly, in education, a deeper integration could revolutionize teaching methods and equip students with advanced skills for the digital future.